Maintenance and Repair Solutions

BIOS is the Reliable Partner of Maintenance and Repair Solutions.

As BIOS, we aim to provide maintenance and engineering services in Mechanical-Electrical-Automation fields in order to prevent production failures in industrial facilities, and to provide quality-time-and price advantages with our past experience in the most optimum time for your planned and unplanned stops. In summary;

- Maintenance, replacement or renewal of process-specific machines.

- For tire factories; We provide support with our expert team for all kinds of maintenance and revision-projects for Banbury changes-Exturder-Kalander and Press lines.

- Gearbox maintenance of all sizes, reducer gear and bearing changes.

- Process-specific conveyor maintenance and revisions.

- Detailed failure analysis and solution suggestions-reporting services.

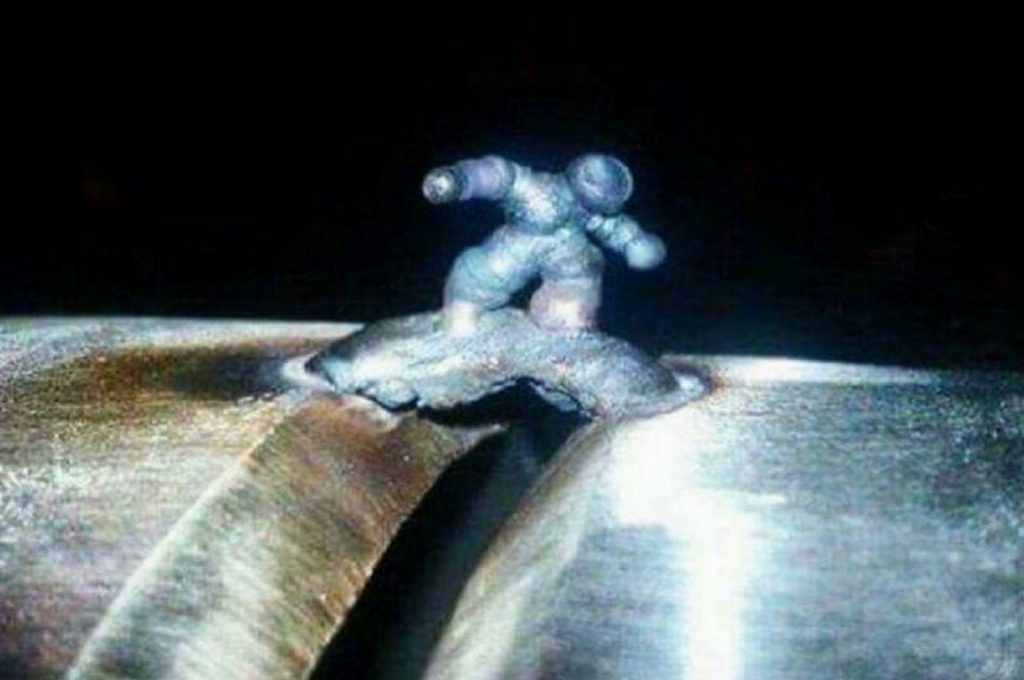

- We provide service with our technical support and solution applications in the matters you need with our certified welding engineer in accordance with international welding standards,

- In factory optimization methodology, we provide services with our expert team in subjects such as TPM, 5S, Kaizen, with our technical support and solution applications.

Also; Consultancy services are provided on periodic, predictive and fault management issues, and technical and labor support is also provided to the engineering units of the companies.

Our maintenance work is performed by our qualified workforce in accordance with our strict Occupational Health and Safety procedures. In this way, we aim to meet the needs of the facilities in the best way by prioritizing the health of the employees.

Our Completed Projects